Earlier in the year I had to finally take my engineering capstone course. This involves forming a team of at least 4 engineering undergraduate students, deciding on a commercially viable product that could be designed to improve on some existing method or system, and implement it, along with providing all details.

One of our team members, formerly a coop student with Analytic Systems (http://www.analyticsystems.com) noted that a possible enhancement to the SolarMax Charge Controller system designed by Analytic Systems, would be to allow for wireless control of the device.

So, what features would this system need? Well, after consultation with Analytic Systems, it was agreed that we would be able to have access to a SolarMax Charge Controller, and all the tools necessary to get the job done. The system would have to do the following:

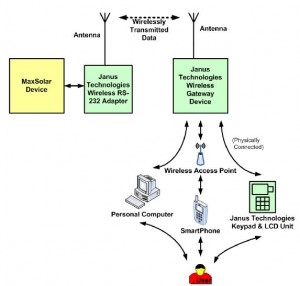

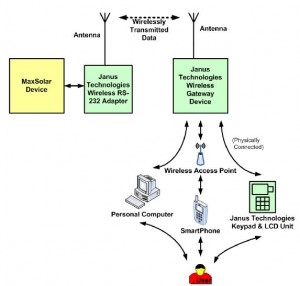

- Send/receive commands and data wirelessly between the SolarMax device, and a centralized hub which we would also design

- Implement a fault-tolerant protocol, with the ability to encrypt the data

- The remote device connected directly to the SolarMax device must be able to transmit data at a distance of at least 100′

- The central hub would have an LCD and pushbutton interface, along with LEDs to indicate data transfer, acknowledge user input, and so on

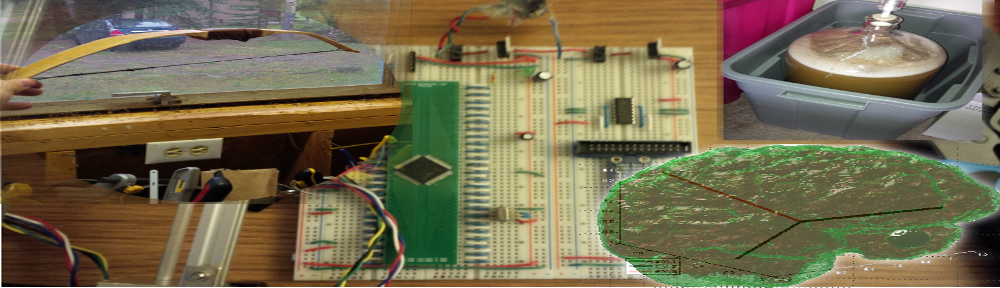

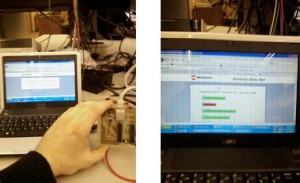

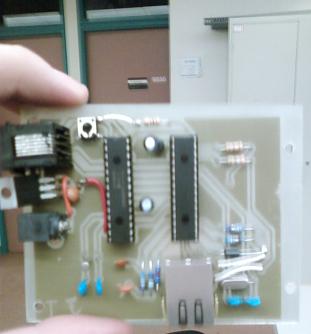

We were able to get a great head start in the implementation stage, as we designed our own circuit boards from scratch, and fabricated them using the toner transfer method and acid etching all the boards ourselves. Combined with weeks of organized coding and development, our final product not only met the initial requirements: we managed to design an entire embedded web server into the central hub (using the PIC24F and ENC28J60 chips, courtesy of Microchip Technologies), which featured Ajax-based dynamic web pages which provided up-to-the-second information from the remote unit. We even managed to configure a basic FTP server with authentication on the micro web server as well, allowing for us to possibly design the system for remote report generation and retrieval in the future.

In addition to this, we managed to extend the range of the device well beyond our initial expectations. Using low power wireless transceiver chips from Linx Technologies, we were able to control the remote SolarMax device with the central hub unit from over 200′ away. With the central hub connected to a wireless router, the project was even more impressive as we controlled the entire system with an iPhone.

Included below is a collection of images summarizing our project and it’s design:

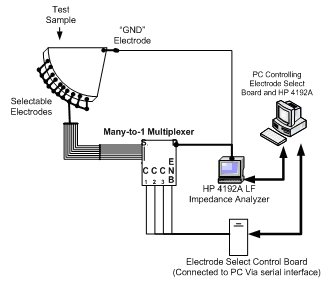

System Overview: Essentially, our product works as a wireless bridge to connect the SolarMax charge controller to a central hub which we also designed. The hub allows for multiple interfaces, including direct access via LCD and pushbutton interface, or remote connection via a networked PC or SmartPhone.

Me acid etching a PCB. Even though we used the toner transfer method, the boards came out perfectly.

One of our testing boards. We built several boards so that each of us could test one in our spare time.

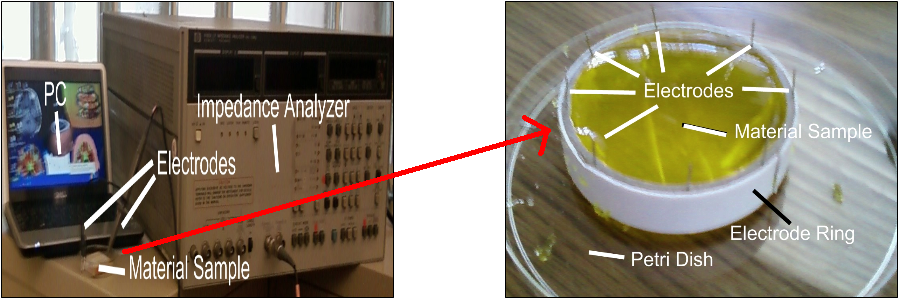

Testing our initial prototype. Were glued to the DMM and oscilloscope for days at some points.

Our redesigned project using a higher quality PCB from Digikey. The design was already small, at less than 4"x3". Not bad considering it has an entire web server running on it, plus interfaces with our wireless transceiver, LCD, and push button circuits

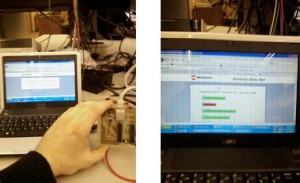

Our final project, connected to a wireless router and being controlled via a PC. We later connected several iPhones to it concurrently and it worked flawlessly.